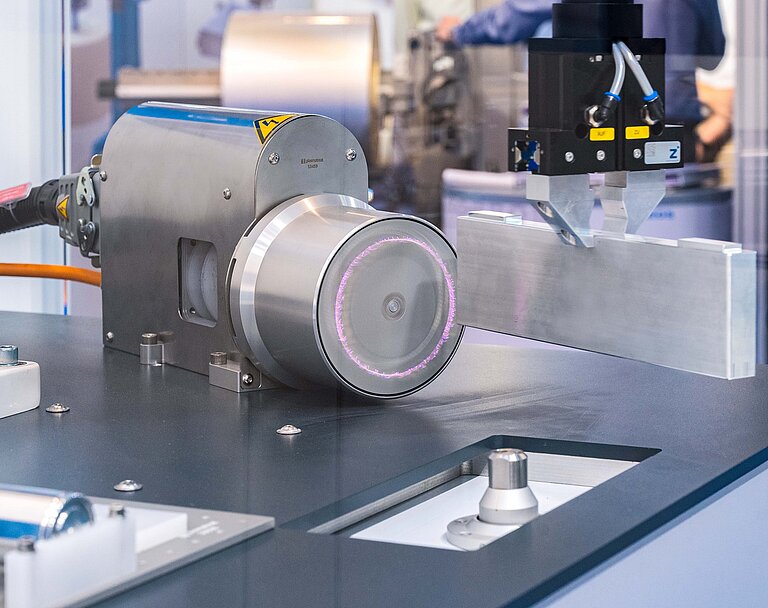

Perfect painting results on surfaces using plasma technology

Explore the remarkable capabilities of this eco-friendly and highly efficient technology live at PaintExpo 2024

Visit us at our booth 1210 in hall 1 and be impressed by the potential of plasma treatment as a pretreatment before painting. Find out how our innovative Openair-Plasma® and PlasmaPlus® technologies can help you not only achieve perfect and durable painting results, but also significantly reduce your carbon footprint in the manufacturing process.

Why should you take a closer look at plasma technology?

Did you know that effective surface treatment is a prerequisite for the subsequent painting process? By pretreating components with atmospheric plasma (plasma cleaning and surface activation), the surface properties are specifically modified. The result is an activated, polarized surface that allows solvent-free painting. This modification ensures reliable adhesion of paints and coatings to metal, aluminum, glass and plastics such as PP, EPDM, and many other materials, increasing process efficiency and protecting the environment.

Plasma, as the fourth state of matter -besides solid, liquid, and gas-, offers numerous advantages:

- Environmentally friendly: Our production is VOC-free and the technology is CO2-neutral

- Gentle and effective: Improved surface properties, even with recycled plastics

- Advanced material selection: New opportunities for material substitution

- Quality and reliability: Improved paint appearance and increased end product quality and customer satisfaction

- Process step reduction: Eliminates washing and priming processes

Learn more at our booth. Visit us at booth 1210 in hall 1 and see for yourself!

Or read on and find out what exactly happens during plasma treatment, and how is it applied in the industry.

You can't make it to the fair? Get in touch with us here!

Plasma: How Does this Exactly Work?

Openair-Plasma® is generated with electricity and compressed air and is even CO2-neutral when green energy is used. All plasma processes are solvent-free, contribute to the environmental balance, can be used site-selectively and can be seamlessly integrated into existing production lines.

Innovative control and monitoring systems from Plasmatreat ensure high process reproducibility. Dry surface treatment with Openair-Plasma® can be carried out in a fully automated process, as an environmentally friendly alternative to harmful chemical processes. Here, the need for additional pre-treatments with chemical primers is eliminated during the activation and fine cleaning of various surfaces prior to bonding, coating, painting, or sealing. Modern, solvent-free or water-based adhesives, paints, and varnishes can then be used. This significantly reduces the emission of volatile organic compounds (VOCs) in production.

Plasma Instead of Chemicals

Using Openair-Plasma® means protecting the environment. Adhesion is really all about surface energy and surface polarity. Since nonpolar materials, and recycled materials, too, in many cases, are often difficult to wet, solvent based adhesion promoters are used to activate the surface. Consequently, adhesion promoters are frequently responsible for over 80% of the VOC-emitting substances used to achieve a reliable bond. Plasma based surface pretreatments achieve clean, highly activated surfaces which can be readily wetted with water, thereby dispensing with the need for VOCs and the associated drying and waste water disposal.

The high surface energy generated by Openair-Plasma® ensures even paint distribution and optimal adhesion. Surface contamination resulting from organic impurities is safely removed. Plasma overwhelmingly reduces the reject rate in countless installations.

New and expanded options for recycled materials

Openair-Plasma® for surface pretreatment makes non-polar (recycled) plastics receptive to subsequent adhesion processes and ensures a strong bond between different, sometimes even incompatible materials. This is the case, for example, when laminating dashboards, which are partly made of recycled materials, with powder-sintered molded skins of soft plastic. In the traditionally used flame treatment technique for the pretreatment of dashboards, all areas of the components to which no adhesion was to take place later had to be covered with thermally stable masks beforehand.

The use of Openair-Plasma® completely eliminates this work step, since the plasma jet works in a location-selective manner and, in contrast to the flame, follows the component geometry with millimeter precision using automated robot technology. In addition, plasma treatment generates very little heat, so that the treated components remain dimensionally stable and can be further processed.

Our Special for You: Win a whole day of plasma testing for your material

No matter for which application – we develop solutions for the pretreatment of any surface and optimize it aligned to your process.

Our atmospheric plasma technology can be a game changer with regards to adhesion characteristics, substrate substitutes or functionalization of surfaces. Find out for yourself easily online: With our worldwide "material test" service you can explore the possibilities of the Openair-Plasma® process first hand.

Give it a try: Our experienced application engineers are looking forward to working with you and find the best solution for your use case. In our well-equipped laboratories, we will pretreat your individual parts with our plasma technology and analyze the results. By clicking the button you automatically accept the conditions of participation.

We are Ready for Your Challenges

Thanks to our global network of sales, service and partners, we can support you wherever you are. Thanks to our expertise and experience, we are ready to help you meet your needs in the field of specialized surface treatment.

Do you have further questions that require a detailed explanation? Book your live appointment at PaintExpo 2024 now, or use our contact form at the bottom to get in touch directly with our surface treatment experts.